It turns out that this is how milk cartons are printed & packaged

Lift the "Veil"

Rich and fragrant milk needs to be stored in a well-sealed

milk carton to perfectly retain the fragrance of the milk.

In order to ensure sealing, the milk carton has four "veils"

covering each other. The outermost is the printed layer,

the middle is the cardboard layer and the aluminum foil layer,

and a layer of plastic film that is tightly adhered to the aluminum foil

layer for complete sealing. There is also another saying that it is

a seven-layer structure, including the adhesive layer between the layers.

Printed version

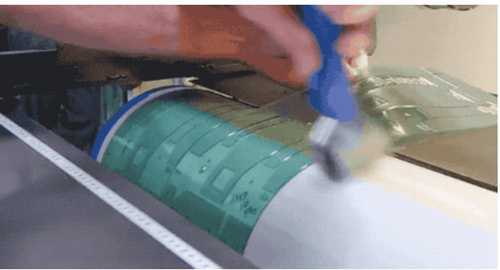

The printing cylinder is a fixed device. For Gable Top packaging that

needs to be printed, workers take the printing plates of each color and

stick them on the printing cylinder.

First printed color

The color comes out of the second printing.

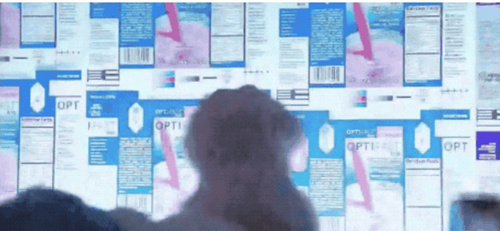

Check under strobe light

When the printing equipment is running at full speed, it is invisible to

the naked eye.In order to better observe the printing effect, a strobe

light is needed. Fix the time interval between lighting and let the page

stay on one printing screen, so that youcan clearly see the effect of

multiple printings and detect whether there is any printing distortion.

The small color blocks on the packaging box are used by printers to

check whether there is overlap or offset. Rumors that the combination

of color blocks represent different additives can be denied. This color

block on the milk carton is used for photoelectric positioning to monitor

the printing effect in real time.

Printed layer

A design worth mentioning in particular is the outermost "veil" of

the milk carton - the printed layer. For this kind of large-volume

outer packaging printing, if the factory prints all the colors at one time,

it will have high requirements on the printing equipment. So I adopted

a very cost-effective and convenient method - multi-color overprinting.

Using the original equipment, a different printing plate is used for each

printing, and only one color is printed at a time. The superposition of

different colors can generate more colors, and up to 6 printings can

meet all color requirements.

After printing and die cutting, the products will be inspected, unqualified

ones will be rejected.

Paste box

After the die-cut products are glued into boxes, a milk box is born.