Want to produce high-quality cartons ? Pay attention to these seven points

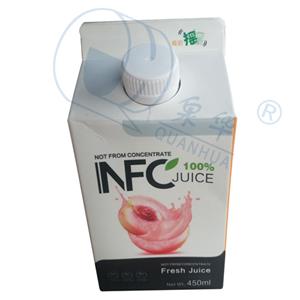

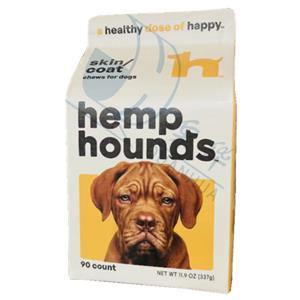

High quality carton production process has the following characteristics, let 's take a look ! 01 material selection The primary feature of the production process of high-quality cartons is the selection of high-quality materials. Generally speaking, the carton is divided into two parts : corrugated paper and surface paper. The corrugated paper selected for high-quality carton should have excellent compressive properties, while the surface paper should have certain wear resistance, moisture resistance and waterproof properties. In addition, factors such as the thickness, density, and flatness of the cardboard need to be considered to ensure the robustness and stability of the carton. 02 design planning High quality carton production process in the design planning focus on details. The structural rationality of the carton should be considered in the design, including the superposition method of the cardboard, the bonding method of the joint, and the strengthening treatment of the bottom cover. In addition, but also to take into account the appearance of the carton aesthetic, thereby increasing the added value of the carton.

03 manufacturing process The production process of high-quality cartons focuses on every detail in the manufacturing process. Firstly, the paperboard is punched, cut, grooved and embossed to improve the flexibility and plasticity of the paperboard. Then, the cardboard is folded into a box, and the adhesive is used for bonding to make the box firm and reliable. Finally, personalized processing such as coding, imprinting, and die-cutting is performed to meet the different needs of customers. 04 inspection standard The production process of high-quality cartons is strictly controlled according to the inspection standards. These standards include carton dimensional accuracy, quality stability, impact resistance, compressive strength, weather resistance, wear resistance and other indicators. Through the sampling inspection and full inspection of the carton, the quality of the carton is ensured to meet the requirements.

05 environmentally friendly high-quality carton production process focuses on environmental protection. First of all, environmentally friendly paperboard is selected as raw material to reduce environmental pollution. Secondly, take energy saving measures, such as the use of waste heat recovery system for energy recovery and reuse. At the same time, we should also pay attention to the recycling and reuse of waste cartons to achieve recycling. 06 high degree of automation and high quality carton production process with advanced automation equipment and production lines to improve production efficiency and product quality. The automatic production line can realize fast cardboard processing, automatic folding and bonding, high-speed coding and other operations, so as to improve the production efficiency and consistency of cartons.

07 Innovative research and development of high-quality carton production process focuses on innovative research and development. Through continuous research and development of new materials and processes, improve the performance and service life of cartons. At the same time, it also meets the personalized needs of customers by continuously improving the design and structure of cartons. In short, the production process of high-quality cartons has the characteristics of scientific material selection, fine design and planning, rigorous manufacturing process, strict inspection standards, environmental friendliness, high degree of automation and innovative research and development. Only by comprehensively considering these factors, can high-quality cartons with good quality and performance be produced.

Get the latest price? We'll respond as soon as possible(within 12 hours)