Quan Hua Packaging's energy-saving, low-carbon, and green manufacturing system helps achieve the dual carbon goals.

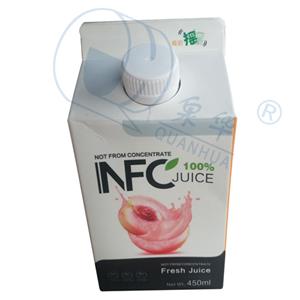

Quanhu's energy-saving, low-carbon and green manufacturing system for packaging helps achieve the dual carbon goalsGreen is the lifeline of Quanhu. As a supplier serving the food and beverage industry, Quanhu first requires that its packaging products must be green secondly, the materials, equipment, and even the processes used by Quanhu to produce these products must also be tagged as "green." According to General Zhao, Quanhu's low-carbon green products also include paper-based composite cartons and high-end food composite card paper. These products are mainly composed of card paper as the main raw material, with a small proportion of food-grade PE and environmentally friendly ink. They are produced using flexographic printing machines and environmentally friendlyographic printing technology. Compared to traditional packaging, they fully meet the functional needs of liquid food customers for food safety, environmental protection and recycling, low-carbon emission, three-dimensional packaging promotion, light transportation, convenient drinking, and smart packaging. Quanhu places great importance on the control and research improvement of raw materials, well as the technological transformation of production equipment. It also requires that production processes continuously improve towards low energy consumption, low emissions, high output, and high quality "In terms of raw material procurement, we prioritize suppliers that provide environmentally friendly products; in the production process, we use the most advanced production equipment in the world reduce waste and continuously optimize processes. Only by doing this can we produce relatively environmentally friendly products," said General Manager Zhao. Speaking of equipment improvement, he recalled,Years ago, we used a carton-making machine that ran at about 110 meters per minute. To match our production capacity, we purchased the most carton-making machine from Europe, which runs at 500 meters per minute. This means that with the same energy consumption, we can produce nearly four the product. This has significantly advanced our goal of reducing carbon and increasing efficiency." In terms of printing equipment, the printing width has increased from 400 to 800mm, and the printing speed has increased from 110 meters per minute to 170 meters per minute. The increase in means that the same energy consumption can produce more products, which is a visible green achievement for the company.