Detailed explanation of dairy packaging

Detailed-explanation-of-dairy-packaging

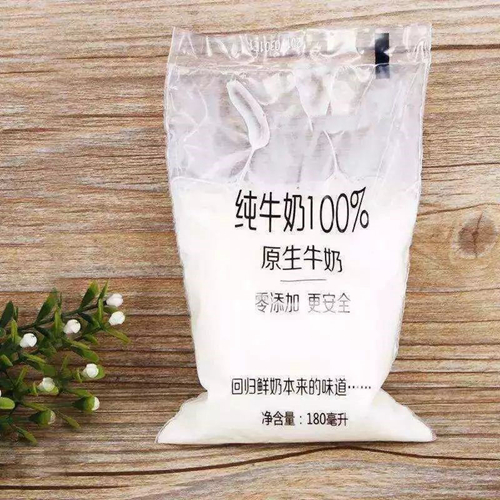

1.Ordinary plastic soft bags

Material PE/ PP/ PA/ PVC, single layer, poor sealing, low price, no light shielding

and UV resistance.

Identification characteristics: soft, thin, translucent, easy to break.

2.plastic stand bag

The material is PP/PA/PET, single layer, thicker, and has relatively good sealing performance.

Most of them have PET bottle mouth and screw cap designs.

Identification features: The bottom shape makes it easier for the product to stand, the surface

is brighter, and the printing can be relatively fine.

3.Bailey bag

The patented packaging of the French company PrePak is mainly made of PE, multi-layer composite, and has a black film layer to isolate light and ultraviolet rays to avoid affecting

the product. High-end products have an aluminum film layer.

Identification characteristics: Opaque soft bag, easy to break. Mid-to-low-end dairy and

plant protein drinks are mostly used.

4.love shell bag

Patented by Swedish Ecolean company, made of PE and calcium carbonate.

Identification features: Soft bag, the whole bag is shaped like a Western-style milk bottle,

has an inflatable handle, and the bottom is designed to stand.

5.Tetra Pak Pillow

Tetra Pak, invented and patented by the Swedish Tetra Pak Company, is currently one of

the most popular dairy and beverage packaging in the world. It mainly comes in three forms:

Tetra Pak Pillow, Tetra Pak Brick, and Tetra Pak House, which can be used for pasteurization

and UHT instant high temperature sterilization. The special feature of the packaging is that it

has at least six layers of composite materials - aluminum foil layer: core insulation layer;

PE layer: main sealing layer to enhance strength and toughness; cardboard layer: support, strength, weight reduction, and also the printing surface. Among them, Tetra Pak pillows are relatively low-cost and suitable for mid- to low-end products.

Identification characteristics: soft bag, but with a certain thickness. Most products are printed

by hob cutting (the pattern unit is about half the area, so pattern alignment can be ignored

during assembly line filling, cutting, and sealing to reduce costs and improve efficiency.

Of course, there are also alignment screens, which are more expensive.) Usually There

will be an eye-catching "Tetra Pak" mark on the packaging.

6.Tetra Pak (Tetra Pak Brick)

The introduction is the same as Tetra Pak Pillow, but the production and filling line

involves pressing and folding, which is more complicated and costly.

Identification characteristics: Cubic shape, small packages have straw holes, and straws

are attached with the packaging; large packages usually have screw caps.

7.Tetra Prisma

Tetra Pak's high-end packaging product has an octagonal body for easy holding and a

screw-on cap for easy drinking. The packaging of room-temperature yogurt such as

Guangming Moslian and Ilian Mushi is a typical representative.

Identification features: octagonal body and screw cap.

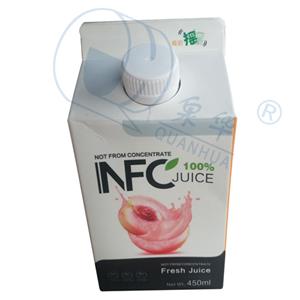

8.Tetra Top

Tetra Top packaging was launched by Tetra Pak in 1986. It is a resealable square package

with rounded corners, with a top polyethylene twist cap that is injection molded and sealed

to the package in one go. The packaging is easy to open, pour and reseal.

Identification features: Square packaging with rounded corners for easy opening, pouring

and re-sealing

9.Combibloc

The technology originates from Germany and belongs to the Swiss SIG Group, which is

Tetra Pak's biggest competitor. In many areas of the world, it even surpasses Tetra Pak.

The structure is similar and is also multi-layered, but the cost is lower than Tetra Pak.

Identification characteristics: Differentiated competition with Tetra Pak, so it exceeds Tetra

Pak in terms of surface printing quality and printing process flexibility. The feel is also stiffer,

but the texture is slightly thinner. Large packages usually also have screw caps or tear-off openings such as Huiyuan Juice.

10.Gable Top Box

This package is basically made of paper pulp, and the PE layer is just a coating.

Unlike Tetra Pak and Combil, which have a metal layer and a PE film layer, the sealing

performance is poorer and is suitable for pasteurized fresh products. Because pasteurized

products usually have a shelf life of less than 15 days, and dairy products only have a shelf

life of 7 days, there is still no problem.

Identifying features: There is a roof! Some have centrally symmetrical roofs, and some have

sloping roofs! There is a roof anyway! It’s just the characteristics of fresh milk.

11.Tetra Pak TT can

It is also a product of Tetra Pak Company, with overall shape and tear-off design, such as

Junlebao Pure Enjoyment.

12.PE (polyethylene)

PE is the world's most produced synthetic resin and the most consumed plastic packaging

material. Polyethylene products are divided into three types: low density, medium density

and high density. Taking advantage of the good heat sealing performance of PE, containers

made of various composite materials can be used to hold various beverages such as milk,

yogurt, and juice.

Identification characteristics: Generally speaking, PE packaging feels smooth, soft and

lubricated, and appears slightly soft when bitten with teeth.

13.PP (polypropylene)

The development of polypropylene transparent packaging bottles has been a hot topic in

plastic packaging at home and abroad in recent years. With the successful development of

the transparent modifier-nucleating agent, adding 0.1% to 0.4% sorbitol xylene (benzaldehyde) nucleating agent to ordinary PP, the highly transparent PP bottles produced can be widely used

in In beverage packaging that requires heat sterilization, such as concentrated juice and other high-temperature filling, it is affordable, pressure-resistant and temperature-resistant, and is a

new competitor to PS, ABS, PET, and PE bottles.

Identification characteristics: Generally speaking, PP has a hard texture and a slightly rough feel. After folding, the creases will be white, and the color is whiter than PE.

14.Polyester (PET or PETP)

PET bottles produced by the two-axis extension blow molding method have the characteristics

of "large capacity, transparency, strong intuitiveness, light and easy to open, refrigerated, easy

to carry, strong, and recyclable", providing broad market prospects for its development . Judging from the market share of major beverage countries in the world, PET bottles account for more

than 70% of the four major beverage packaging of carbonated drinks, juice drinks, tea drinks,

and bottled water.

Identification characteristics: It has good transparency, high surface gloss, and glass-like appearance. It is the most suitable plastic bottle to replace glass bottles.

15.fantasy cover

The Dream Cap was mainly born to solve the need for drinking on the go. The design fully integrates the concept of ergonomics: the Dream Cap has a higher neck, and the opening

method is convenient, fast, safe and hygienic. The unique "cover holder" at the bottom can be

used with The jaws fit perfectly, allowing consumers to enjoy delicious drinks anytime and anywhere without any worries.

Identification features: Dream lid packaging breaks through the traditional drinking form of

straw, and has the characteristics of being portable, ready to drink, and drinking on the go.

16.Yogurt in cups

Cup packaging is mostly used for yogurt, and the packaging is divided into plastic cups and

paper cups. With the diversification of yogurt categories, cup yogurts with meal replacement functions now have a compartment added to them for products such as nuts.

Identification features: Like a cup, it can be easily identified from its appearance

Except the above materials, there are many products packaged in other materials on the

market, including glass jars, porcelain jars, aluminum jars, etc., all of which are quite

thoughtful.